Wafer transfer techniques for semiconductor production: choices and challenges

In semiconductor production, wafer transfer is a critical step to ensure the quality and reliability of electronic devices. Wafers are disks of silicon or other semiconductor materials on which thousands of microcircuits are etched to be cut and mounted in electronic components such as chips and sensors. Wafer transfer involves moving wafers from one production step to another without damaging them or altering the properties of the circuits they contain.

There are several wafer transfer techniques, each with its own advantages and disadvantages. In this article, we will review the major wafer transfer techniques for semiconductor production, the choices manufacturers must make, and the issues that must be considered to ensure efficient, high-quality production.

1. Manual wafer transfer

Manual wafer transfer is the oldest and simplest method, which consists in manually transporting the wafers from one production step to another using a wafer carrier. This technique is still commonly used for small-scale production or for research and development processes. However, it presents significant risks of wafer damage, contamination and time loss, due to the need to manually handle each wafer.

2. Robotic transfer

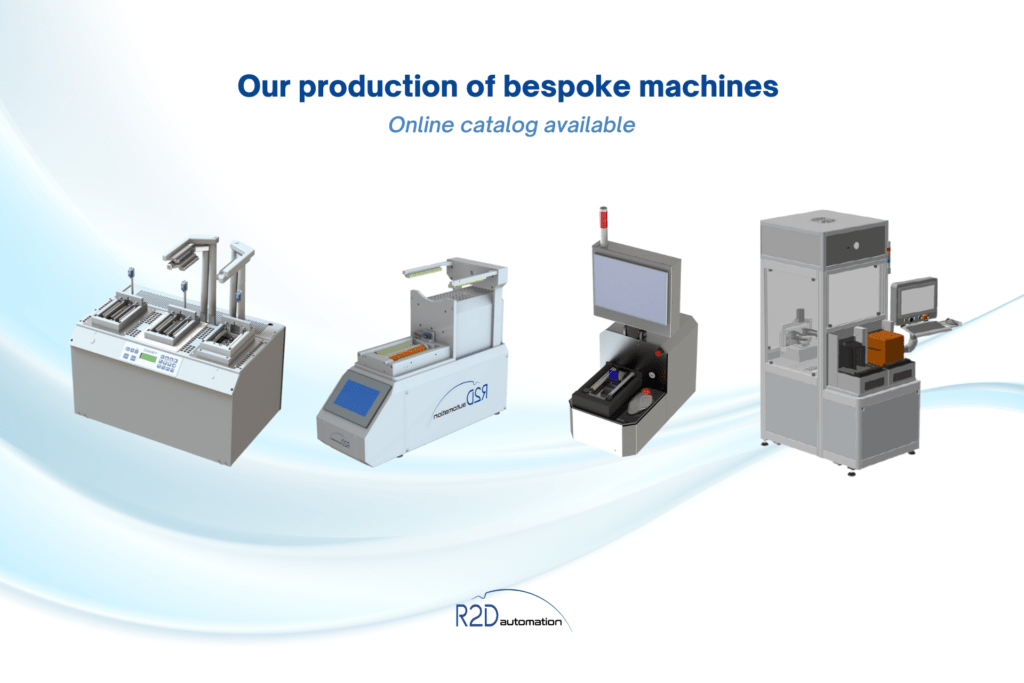

Robotic transfer is a more advanced method that uses robots to move wafers between different production steps. This technique has several advantages over manual transfer, including greater accuracy, reduced risk of contamination and increased productivity due to the ability to transport multiple wafers at the same time. At R2D Automation we offer a wide range of wafer transfer machines.

In conclusion, the choice of wafer transfer technique is crucial to ensure semiconductor quality and reliability. Manufacturers must consider various factors such as production size, capital cost, productivity requirements, contamination risks and safety precautions to choose the most appropriate wafer transfer method.

For a more in-depth look at the topic, we recommend the following references:

“Semiconductor Manufacturing Handbook” by Hwaiyu Geng, which provides an overview of semiconductor manufacturing technologies, including wafer transfer techniques.

“Wafer Bonding: Science, Technology, and Applications” by Qizhen Li and Alain Diebold, which describes the various wafer bonding techniques, including adhesive film transfer.

“Robotics in Semiconductor Manufacturing” by Stephen J. Krause and Karl F. Böhringer, which discusses robot applications in the semiconductor industry, including robotic wafer transfer.

“Cassette-to-cassette wafer transfer system” by Tomohiko Haga et al, which presents a cassette wafer transfer system for large-scale production.

Using these references, manufacturers can better understand the advantages and disadvantages of each wafer transfer technique and make informed choices to optimize their semiconductor production.