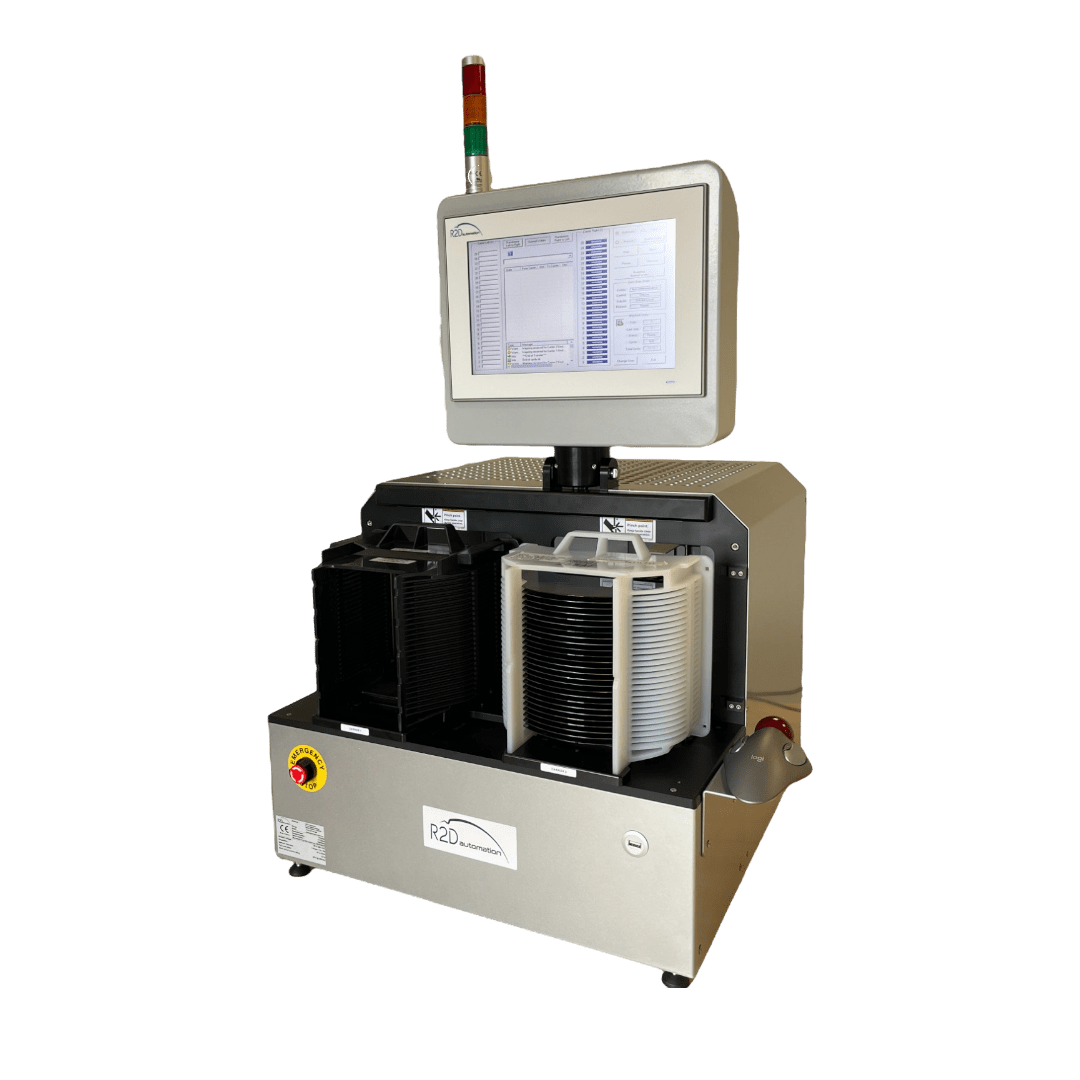

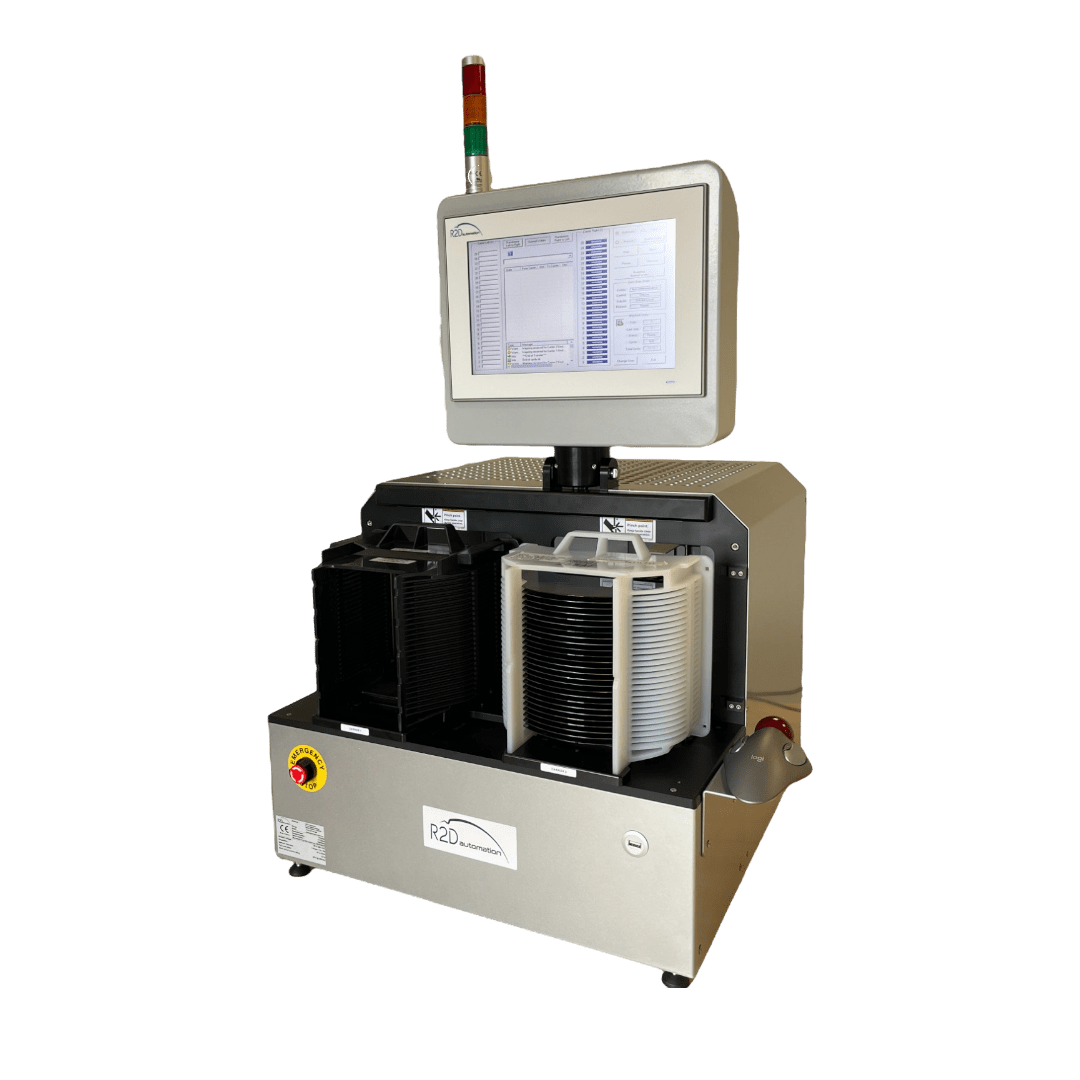

The Table Top Organizer is a single wafer pick & drop machine, transferring wafers within or between cassettes.

Under control of a touchscreen panel PC, all user commands and equipment maintenance are done through the smart R2D Automation interface. Moreover, the Table Top Organizer is also compatible with SECS/GEM communication, TCP/IP – E37 HSMS-SS logical protocol, thanks to its Ethernet communication port available on the rear side of the machine.

Once cassettes placed on load ports, the Table Top Organizer maps cassettes, detecting wafers presence and position, detecting cross or double slots, and then reporting the result on the touch screen interface. Then, the user can perform pre-programmed recipes as randomization, compacting, completing, copying, or inverting recipes. The user can also create his own recipes and manually transfer the selected wafers. All transfers are instantly reported to the interface.

Customized according customer cassettes and wafers, the Table Top Organizer can handle 6″ and 8″ wafers on the same machine (automatic size detection), and is compatible with thin wafer up to 150µm on 6″, 180 on 8″, from various substrate materials. Depending on wafers warpage and customer requirements, we propose different shapes and materials of backside vacuum or edge contact end effectors, that will ensure the best safe handling of your wafers. The Table Top Organizer ensures a safe wafer handling through its numerous safety sensors active throughout the transfer, detecting cassettes and wafers presence and placement at every stage.

Key system features

Standard features

Specifications

Software & Interface

Performance

Facilities and Requirements

Options: